Discover the phases of cardboard recycling that give an old box new life.

Cardboard is one of the most frequently used materials around the world. Estimates reveal that over 80 percent of all food and products sold in the United States are packaged in cardboard, which amounts to about 100 billion boxes used per year. With cardboard and paper contributing to 41% of solid waste streams and using up to 1 billion trees each year, there is something we can do with all that cardboard to help protect our natural resources: recycle it.

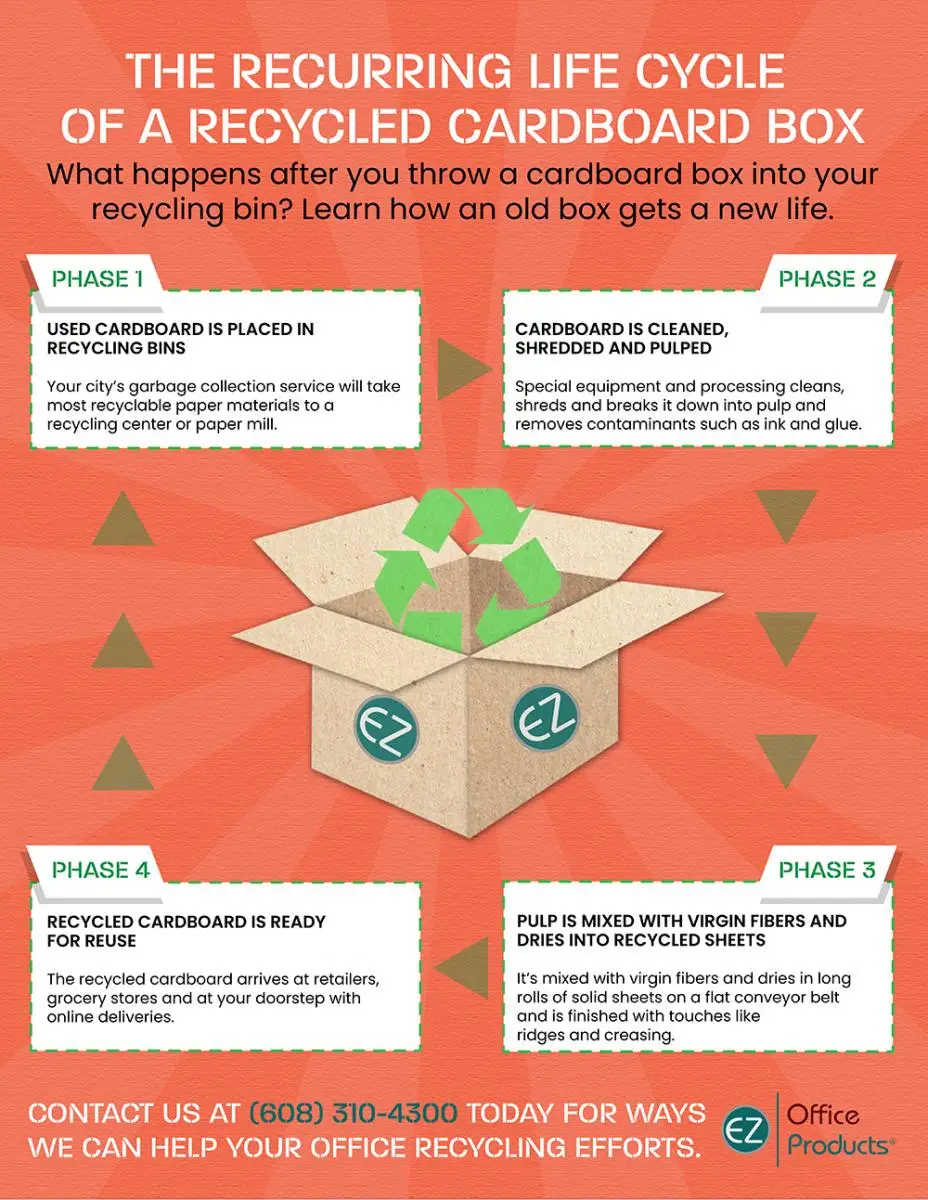

Industry experts estimate that recycling just one ton of cardboard can save 17 trees, 6.6 million BTUs of energy and 7,000 gallons of water – not to mention oil, electricity and precious landfill space. So, what exactly happens during the cardboard recycling process that makes such a significant impact? Here is a summary of the recurring life cycle of a cardboard box:

- Phase 1: Used cardboard is placed in recycling bins

- Phase 2: Cardboard is cleaned, shredded and pulped

- Phase 3: Pulp is mixed with virgin fibers and dries into sheets

- Phase 4: Recycled cardboard is ready for reuse

Keep reading to learn more about these steps in the cardboard recycling process.

Phase 1: Used cardboard is placed in recycling bins

The first step in cardboard recycling begins when you place a cardboard box in your home or office recycling bin. Your city’s garbage collection service will take most recyclable paper materials to a recycling center or paper mill, where it will begin its journey to become usable cardboard once again.

Phase 2: Cardboard is cleaned, shredded and pulped

Once a paper mill receives the cardboard, they will place it through an exhaustive cleaning process. Your boxes will be shredded, then soaked in water and a chemical solution to break them down into “pulp.” This pulped material also undergoes additional cleaning for removal of contaminants such as tape, glue, staples and ink.

Phase 3: Pulp is mixed with virgin fibers and dries into sheets

The next step in the lifecycle of a cardboard box is the mixing and drying process. Once the cardboard is in a cleaned pulp state, it’s mixed with virgin fibers and dries in long rolls of solid sheets on a flat conveyor belt. Once dry, the sheets might be glued together in layers, sent through a metal rolling machine to add ridges, or shipped to boxboard manufacturers for finishing touches, like shaping and creasing.

Phase 4: Recycled cardboard is ready for reuse

Once the finishing is complete, the recycled cardboard arrives at retailers, grocery stores and at your doorstep with online deliveries.

Every time cardboard undergoes recycling, the fibers become weaker. For this reason, cardboard can only sustain this process up to 8 times. Next time you see a cardboard box, consider reusing the material to store items in your home or use these other cardboard repurposing solutions to extend its life instead of discarding it after you unwrap your package. Toss it into your recycling bin when it is worn past the point of usability so it can undergo another round of this cardboard recycling process.

As a supplier of office supplies that are often transported in cardboard boxes, we do our part to reduce our carbon footprint. From shipping boxes back to our suppliers for reuse to delivering orders to our customers in reusable bags instead of cardboard, protecting the environment remains at the forefront of our mission.

Recycling around the office doesn’t have to end with cardboard boxes! Learn more about recycling the everyday products you use with our Recycling Office Supplies 101 Guide. For more articles on environmental sustainability, recycling office supplies, and other tips for making your office more eco-conscious, check out our blog today.

Shop for eco-friendly office supplies online from our environmentally responsible suppliers now or call our local customer concierge to set up your business account at (608) 310-4300 today.